VessFire

VessFire is developed for time-dependent, non-linear analysis of thermo-mechanical response of process segments and process equipment (vessels and piping) during blowdown, with or without exposure to fire.

VessFire captures all relevant physical phenomena which take place in these scenarios.

VessFire is used by clients and projects world-wide and is recommended by several oil companies.

VessFire has since 1998 been developed taking into consideration the following:

- Blowdown is a fast, transient and highly dynamic process

- The analysis must handle phase changes, both evaporation and condensation, and flash calculations are thus performed at each time step

- The phases are not in equilibrium, and composition of phases will vary with changes in pressure and temperature

- Gas is compressible

- The 3D nature of physical objects cannot be disregarded

- Heat exchange through vessel and pipe walls is essential, particularly when vessels and pipework are exposed to fire

- Heat transfer between phases

- Simplifications can result in incorrect results

VessFire is the most complete simulation system available for performing blowdown calculations. It is built upon our proprietary multi-physic simulation system Brilliant.

VessFire is extensively tested and bench-marked against experiments and other codes.

The requirements to simulation of depressurisation now described in API 521 6th edition (2014) are the same as VessFire always has been based on.

VessFire areas of application include:

- Depressurisation analysis during fire exposure

- Analysis of low temperatures during cold blowdown

- Calculation of release rates

- Determination of time to rupture and process conditions at rupture

- Sizing of blow down orifices

- Design of an arrangement with multiple blowdown valves

- Optimisation of process plant safety (passive fire protection, blowdown valve sizing, pipe schedule, etc.)

- Determination/verification of fire areas (process sectionalisation)

- Assessment of rupture criteria

A trusted tool

Process plants must be designed to prevent escalation in case of a fire scenario. The most recognized method of ensuring this is to run a fire simulation on a model of the plant. With VessFire, the user can verify the design of process pipes and equipment by putting them through a simulated fire scenario.

Technical Description

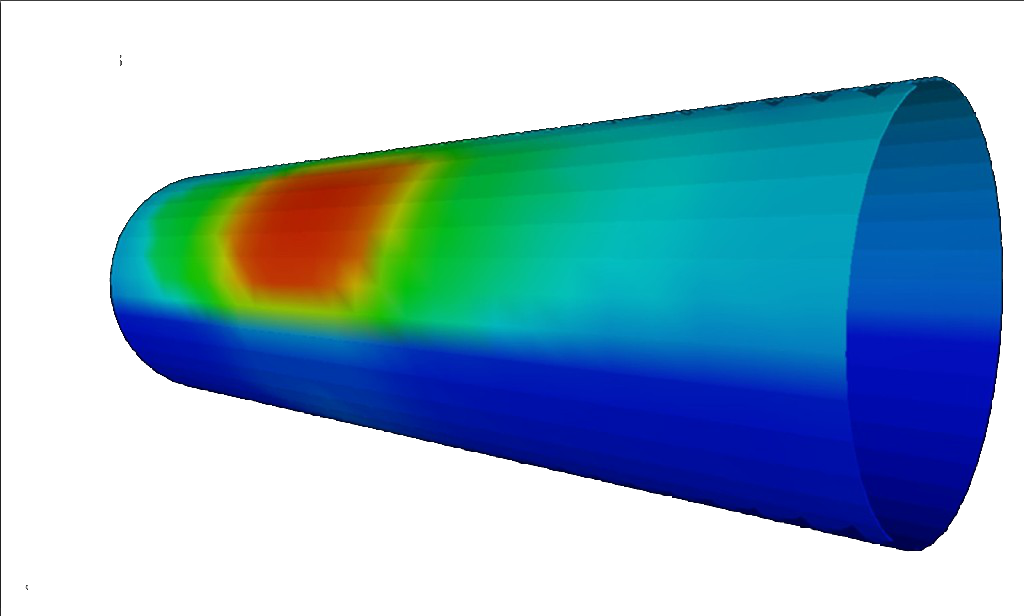

VessFire solves the problem of heat transfer, conduction, thermodynamics of object contents and stress using a coupled approach. The following capabilities are included in the program and all are simulated with respect to time.

The precedence of VessFire lies in the dynamic calculation of thermodynamic and mechanical interactions. This includes:

- Heat transfer from a fire to the fluid through insulation and steel.

- Energy transfer within the segment

- Mass transfer between liquid and gaseous phase in the segment

- Mass transfer to flare header

- Non-linear stress calculation

For more information on VessFire, visit our Downloads and links section.

Questions relating to VessFire? Contact us, or visit our frequently asked questions:

Do you want more information?

Please send us an enquiry, and we’ll be in touch as soon as possible. We always look forward to hear from you!