The Next Generation of VessFire is here!

VessFire2 is now available to customers on a service basis. VessFire2 is the next generation dynamic simulation system for flow analysis, depressurization, and fire integrity of process systems. It is dynamic, 3D, and it handles single phase and mixed phases, and phase transitions. As VessFire1, VessFire2 complies fully with API 521 (2014).

Flow analysis

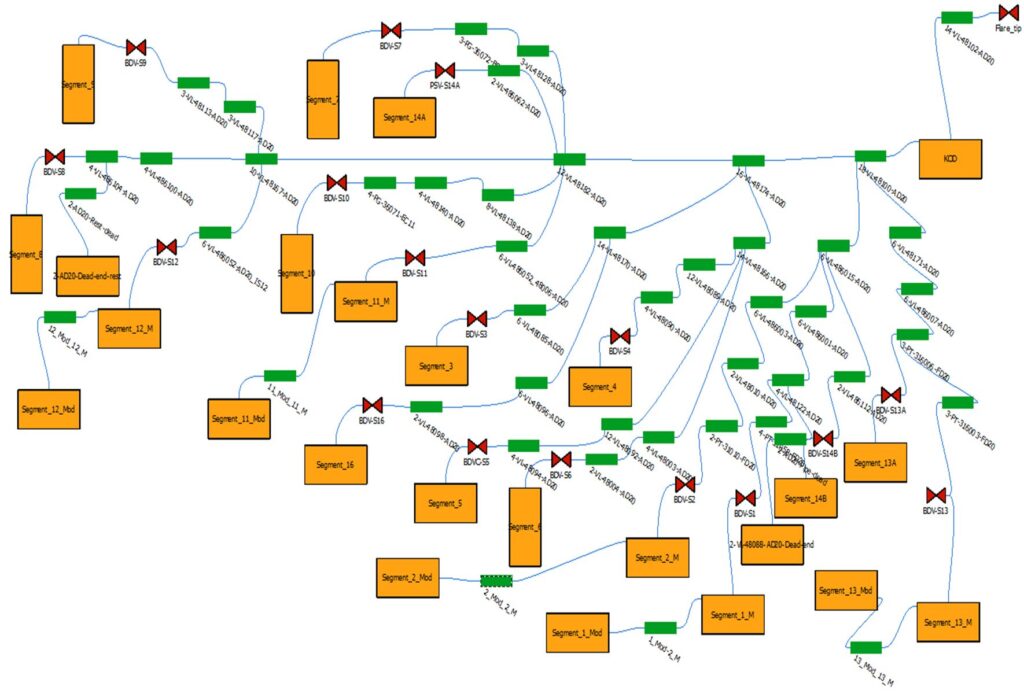

VessFire2 allows for simulation of complex systems with multiple vessels, multiple compositions, and process conditions, and multiple BDVs and PSVs. VessFire2 provides the opportunity for dynamic flow analysis of pipeline systems.

VessFire2 includes a modified Peng-Robinson EoS which allows for determining if formation of solid CO2 is a risk, telling where, when, and how much dry ice that is formed. Other EoS are available for pure CO2 and water.

High and low temperatures

The thermodynamic library ThermoProp contains more than 220 components, and pseudo-components can easily be defined.

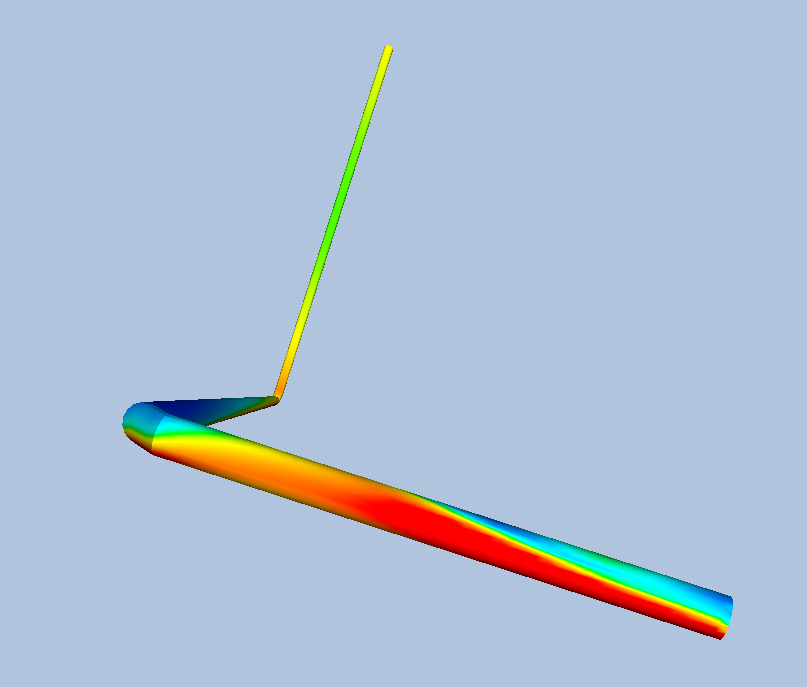

The system handles cold blowdown and blowdown with process systems exposed to fire. VessFire is thus the excellent choice for analysis of fire integrity of pipes and vessels. It is also an excellent choice for studying low temperature issues.

VessFire has a database with high temperature material data for different steel qualities and insulation materials. Multiple layers of insulation can be added.

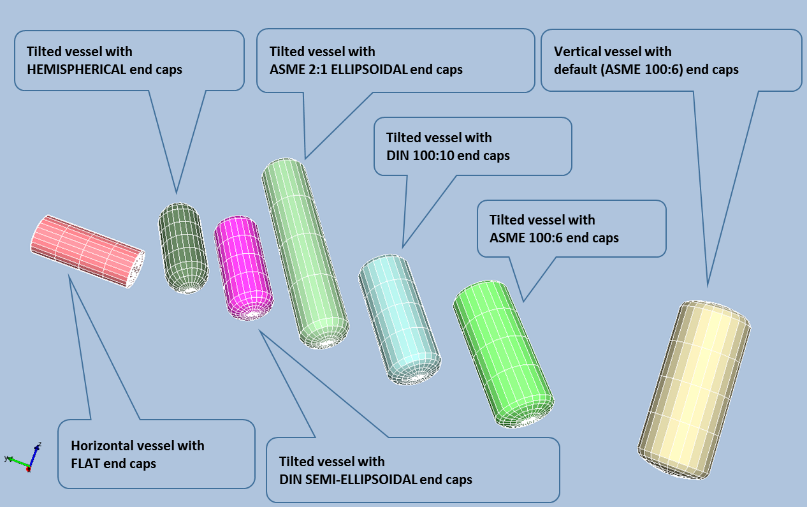

A number of vessel types are available defined by end cap geometry.

Flow in pipes considers friction losses due to bends, roughness.

Fire loads can be defined freely and be adapted to any fire scenario.

Applications

VessFire2 has been applied on cases including offshore and onshore oil & gas, involving fluids with CO2 content from 0 mol% to more than 70 mol%, and LH2.

The system has been validated by cold blowdown experiments for pure CH4, pure CO2 and mixtures of CH4 and CO2. VessFire has also been validated against jet fire tests and other experiments involving exposure of test specimen to high temperatures, and it has also been bench-marked with other tools. VessFire is “in the middle of the road”!

Application areas include:

- dynamic depressurisation analysis of segments and total plants

- optimising the blowdown and pressure-relief arrangement with use of multiple BDVs with individual characteristics, and PSVs with different opening profile and set points.

- dynamic analysis of flare systems, complete header, identifying amounts of condensation, formation of solids, and low temperatures

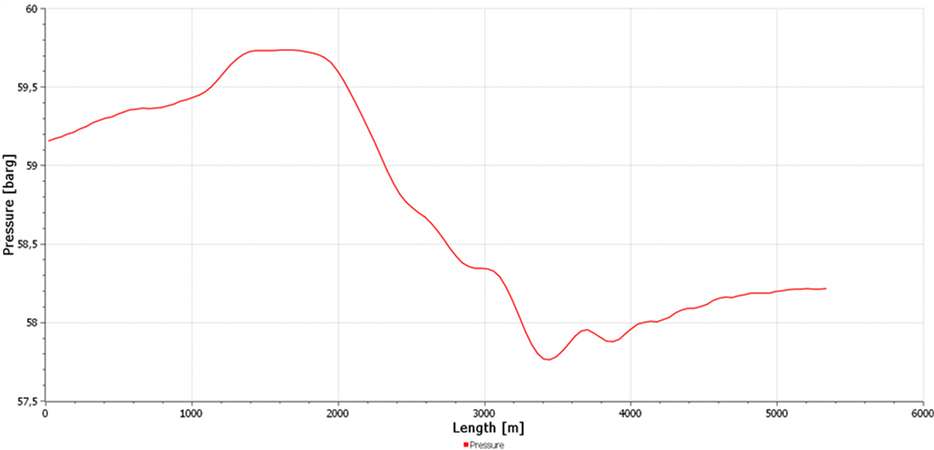

- dynamic flow analysis of pipelines

- assessment of leak detection options for pipelines

- fire integrity of pipes and vessels, calculating time to rupture and leak rates

- optimizing design by thorough, complete, and consistent analysis capturing material properties of pipes and vessels, insulation, process conditions and thermodynamics

Output

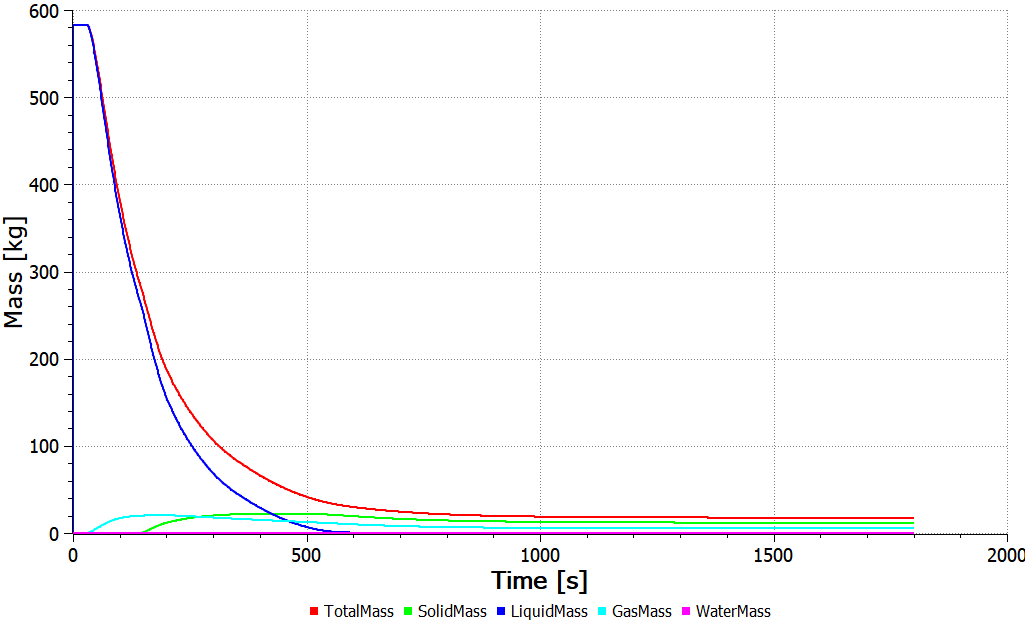

Output from simulations include mass content in vessels, pipes and the entire segment, flow rates through valves, pressure, temperature in fluid and pipe wall and vessel wall as a function of time. A new feature in VessFire2 is length plot; a value of a parameter (mass and volume fractions, density etc.) can be shown at a specific location as a function of time.

Do you want more information?

Please send us an enquiry, and we’ll be in touch as soon as possible. We always look forward to hear from you!