FAQ

-

What information do I need to set up a case in VessFire?

- P&ID covering the segment

- Layout of segment

- Length of pipes

- Pipe specification for the relevant pipes in the segment (diameter, wall thickness, material type, corrosion allowance, mill tolerance)

- Phase type for all pipes. Pipes are taken to be either fully liquid or fully gas

- Ultimate tensile stress (UTS) for material in pipe and vessels

- Diameter, wall thickness and length of vessel

- Liquid level in vessels

- Composition entering the segment (inventory)

- Temperature and pressure of inventory (usually operational conditions).

- Heat exposing scenario (heat load, time duration)

- Ambient temperature

- Information about blowdown valve (BDV) (activation time including registration of fire), pressure safety valves (PSV) (set pressure, full-opening pressure and reset pressure) and upper limit for the release rate

-

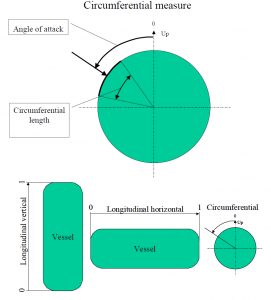

How should “longitudinal position” and “angular position” be set? Can we define a blowdown valve at the bottom of a vertical or horizontal vessel?

If you have a horizontal vessel, you can change the angular position from 0 to 180 degrees. 0 degrees at the top of the vessel, and 180 at the bottom. If you have a vertical vessel, you let the longitudinal position be 0 (bottom) and the BDV, or PSV if you like, will be placed at the bottom.

Questions related to use of VessFire

-

What is the calculation sequence for a typical VessFire algorithm?

- Geometry set up and material property collection.

- Initiation of calculation.

- Flash calculations to find composition in liquid and gas as well as evaporation, condensation and phase properties.

- Release rate calculations.

- Calculation of liquid height, pressure and density.

- Calculation of heat transfer coefficients.

- Calculation of inventory governing equations for liquid and gas.

- Calculation of external heat load.

- Calculation of temperature distribution in vessel shell considering external heat load and inventory temperature.

- Calculation of shell stress and comparison to the acceptance criteria for the elevated temperature.

- Next time step starting at step 3 and repeating all steps up to 11.

-

Why is water and hydrocarbon level listed as inputs? Are not inlet composition, temperature and pressure sufficient to calculate the different phase volumes?

The water, HC liquid and gas volume fractions could indeed be obtained from these initial parameters. However: Small deviations in composition would imply large deviations in volume fractions, and therefore also in total mass for the segment. The inlet composition is not necessarily the same as the global segment composition. Liquid and water levels are widely measured and serve as more consistent parameters for calculating phase volumes than the composition. In conclusion, VessFire finds the phase compositions from flash-calculations, but not the size of each phase.

Technical questions

-

I’m getting the error message "No valid scenario file available in directory"

Check your file path. If you have the period symbol in your path, remove it and try to run the case again.